In the last four months, Rhode Island Carbide Tool Co. in Smithfield has installed four new pieces of equipment to make cutting grinders and tools for CNC, or computer numeric control, operators.

“We’ve spent more than $2 million on equipment in the last two years, and we wouldn’t be doing that if we weren’t busy,” said company President John Lombari.

Yet, finding qualified technicians is a challenge, particularly CNC operators who manipulate machines through computer programming instead of manually, he said.

“What we’re looking for is that kid that comes in, pays attention, has good math skills and shows up every day,” Lombari explained. “And we tell them they can come in, earn a good living and support a family. But educators are telling us we really have to get to the parents.”

While Lombari and others say parents tend to push their children toward college, which may not be necessary for students pursuing a career in manufacturing, the various paths being developed by educators and business leaders today include tracks that lead to college as well as those that don’t. Programs need to be comprehensive, these experts say, because opportunities in manufacturing are going unfilled, not only because of an identified “skills” gap, but because of a gap in interest.

Among youth, this apparent lack of interest in, and awareness about, available jobs in manufacturing and the pathways to them, is pronounced, entrepreneurs and educators say.

Briar Dacier teaches machine technology at the William M. Davies Jr. Career and Technical High School in Lincoln, and he is having trouble reaching not only the students, but at times the parents, when trying to encourage them to pursue machine technology as a career path.

“Their image of manufacturing – they can’t picture it,” Dacier said. “When someone says, ‘Do you want to be a chef?’ they know. When someone says, ‘Do you want to join machine technology,’ they don’t know the high-tech manufacturing of today versus the old manufacturing of yesterday. That’s where our biggest roadblock is.”

Dacier and his colleagues at Davies are working to revise the curriculum using CNC machines and by trying to teach use of them in the 11th grade. Dacier is also hoping to purchase more advanced CNC machines by next fall, he said.

“Starting even in the K-12 years, the focus has moved so far away from woodshop, machine shop and drafting courses, that they’re simply not offered anymore. So kids coming up through those grades aren’t being exposed to them,” said Ruth Gobeille, communications manager for the Rhode Island Manufacturing Extension Services in Providence.

McCourt, Dave Chenevert, president of Swissline Precision Manufacturing Inc., in Cumberland, and others, are developing a program to bring business employers into the schools to educate and entice students about the new opportunities in manufacturing.

Spearheaded by Chenevert, this manufacturing-skills initiative involves some coordination and is taking some time because “we don’t want to go into the schools unless we’re fully prepared,” said Chenevert. At Swissline, he has 53 CNC machines and is training internally to deploy them, but hopes to bring in young technicians, he said.

“In order for us to expand or think about expanding, we need to have a pipeline of students to further train,” Chenevert said. “Manufacturers are not looking for the state of Rhode Island to train our employees. What we’re looking for are basic skills in basic math and soft skills, and the ability to want to learn, work, speak, write – all those basics. And we’ll take it from there.”

From middle school on up, disparate educational programs in place or in development across Rhode Island are starting to draw students into manufacturing.

For the past three years, the Providence-based Center for Dynamic Learning has offered STEAMM (Science, Technology, Engineering, Art, Math and Manufacturing) training programs to youth in grades 6 through 12. Since 2008, its SLIDE (Science Learning Industrial Design Engineering) program has given certificates of completion to about 2,200 students, said Kevin Cunha, the center’s chief operating officer and a mentor to several students.

Cunha is also a center co-founder and director of STEAMM studies.

“I found an extreme amount of interest on the part of middle school students building things with their own hands,” he said.

One SLIDE activity involved high school students in a Center for Dynamic Learning “Manufacturing for Change” course who studied the special needs that students have at Meeting Street, in Providence, involving wheel chairs, walkers and PT equipment. They then designed 3-D models and built prototype products to modify that equipment, including modifying a walker so the student could carry a lunch tray while walking, said Margaret Knowlton, head of school at Meeting Street.

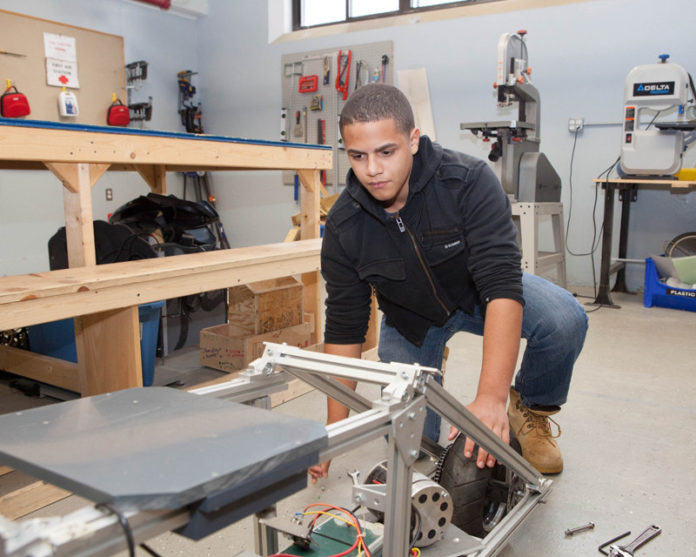

Christian Rijos, 15, of Woonsocket, a student at the Metropolitan Regional Career and Technical Center in Providence, is the type of student that employers like Lombari are looking for. Both manufacturing and college are on his radar. Fascinated by math and engineering, he hopes to attend Worcester Polytechnic Institute and the Massachusetts Institute of Technology and forge a career designing manufacturing tools that save companies money.

Rijos has participated in Center for Dynamic Learning classes, been inspired, he says, by Cunha, and hopes to develop a long-term manufacturing career.

“I want to do it. It’s a good career path,” he said.

Said McCourt: “Once we identify a program like CDL that works, and best practices, then how do we develop that? You can’t clone Kevin [Cunha], but can we clone the program? How do we get these things to work across the state? It starts with awareness.”

The Community College of Rhode Island has an Integrated Manufacturing Center, where two new courses are being taught, “Introduction to CNC Manufacturing” and “CNC Manufacturing and 3-D Modeling.” Both produce credits transferrable to degree programs at other institutions of higher learning, said Richard H. Coren, CCRI’s director of marketing, communications and publications.

Twelve students are taking the first class and eight of them plan to take the second, he said.

“Many of the students coming here are looking for career opportunities or are unemployed,” said Jerry Bernardini, chairman of the engineering and technology department at CCRI. “We’re trying to get the message out. What we’re hoping to do is start a groundswell” of interest.

At the New England Institute of Technology, where preparing students for manufacturing and technology careers has always been part of the school’s mission, a new Shipbuilding Advanced Manufacturing Institute is being developed and already has some students whose classes are paid for with grant money, said Steve Kitchin, vice president for corporate education and training.

SAMI has been funded with a $2.5 million grant from the U.S. Department of Labor, $250,000 from the Governor’s Workforce Board and $50,000 from The Rhode Island Foundation. The latter grant stipulates using the money to attract students to manufacturing, so SAMI is developing tools to do that, including a website, blogs and videos, Kitchin said.

Although manufacturing employment numbers have dropped from 80,000 in 1991 to 40,000 in 2012 in Rhode Island, Kitchin said, the value of manufacturing output for the state has remained constant, at $4 billion or more each year.

At RIMES, Gobeille is working with the Governor’s Workforce Board to define career pathways with associated and as-yet undefined industry standards.

“We’re finding the career pathways aren’t so straight. They’re more like a tree,” Gobeille said, referring to jobs from machinist to welder to CNC operator. “The person needs to get a basic understanding of manufacturing. Once they see that, there are huge opportunities out there. A young person coming through that system might be making $40,000 to $60,000 a year and not have a $150,000 student loan hanging over them.”

A new six-month program launching this summer will take students who recently graduated from high school and put them through the CNC program previously designed for adults, said Barbara Jackson, president and CEO of Workforce Performance Solutions in Smithfield.

The program includes college credit recommendations. Colleges and universities have agreed to accept students if they have a certification from the Manufacturing Skills Standards Council. The program may accept up to 25 students and will cost $7,900, she said.

“We think of ourselves as an employment and economic-development program,” Jackson said. “We don’t talk about ‘butts in the seats.’ We talk about how many people we can get jobs for.

“We’re trying to create employable employees so manufacturing can be expanded. That’s our goal: to expand manufacturing in Rhode Island and America. We have a high placement rate. My goal is to have everybody placed before they graduate,” she said.

Nomar Perez, 17, of Pawtucket, has taken classes through the Center for Dynamic Learning that led to his ability to use computer-design programs and welding tools. He’s always wanted to be an engineer, because he has an innate curiosity about how things work. A wall he helped design and build to keep sawdust from seeping into hydroponic systems for plants and fish has generated attention from his classmates.

“A lot of the freshmen this year and some of the sophomores are very interested in the CDL programs, Manufacturing for Change, I and II,” Perez said. “They ask me about what I’ve done and what they do there. A lot of them would be interested in manufacturing.” •