PROVIDENCE – A new study authored by Brown University researchers shows how metals can be patterned at the nanoscale to be more resistant to fatigue, a condition that results from the slow accumulation of internal damage from repetitive strain.

The study, published in the journal Nature, showed that boundaries in a metal’s atomic lattice with identical crystalline structures – known as nanotwins – can help to stabilize defects associated with repetitive strain and limit the accumulation of fatigue-related damage.

“Ninety percent of failure in metal components and engineering structures is through fatigue,” said Huajian Gao, a professor in Brown University’s School of Engineering and corresponding author of the new research. “This work represents a potential path to more fatigue-resistant metals, which would be useful in nearly every engineering setting.”

Gao co-authored the study with Haofei Zhou, a postdoctoral researcher at Brown, along with Quingson Pan, Qiuhong Lu and Lei Lu from the Chinese Academy of Science.

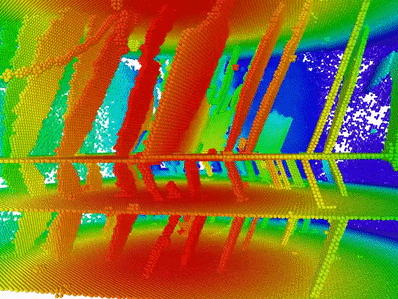

To study the fatigue effects of nanotwins, the researchers electroplated bulk samples of copper with closely spaced twin structures within the plates’ crystalline grains. Then they performed a series of experiments in which they stretched and compressed the plates repeatedly at different amplitudes of strain and measured the material’s associated stress response using a fatigue testing system.

The tests showed that the stress response of the nanotwinned copper quickly stabilized at each strain amplitude. More importantly, Gao said, the study found that the stress response at each strain amplitude was the same during the second half of the experiment, when the metal was cycled through each strain amplitude a second time. That means the material did not harden or soften under the strain as most metals would be expected to do.

“Despite having already been through thousands of strain cycles, the material showed the same stress response,” Gao said. “That tells us that the reaction to cyclic strain is history-independent – the damage doesn’t accumulate the way it does in common materials.”

For comparison, the researchers performed similar experiments on non-nanotwinned samples, which showed significant hardening and softening (depending on the material) and displayed the type of cumulative fatigue effects that are common in most metals.

Gao’s research group has worked extensively on nanotwinned metals. He and his colleagues hope this latest research will encourage manufacturers to find new ways of creating nanotwins in metals.

“It’s still more of an art than a science, and we haven’t mastered it yet,” said Lu, one of the corresponding authors from Chinese Academy of Sciences. “We hope that if we point out the benefits you can get from twinning, it might stimulate fabrication experts to find new alloys that will twin easily.”

The research into nanotwinned metals was supported by the U.S. National Science Foundation and the National Natural Science Foundation of China.

Galen Auer is a PBN contributing writer.