If you are traveling to Europe and hoping to play one of the continent’s favorite sports, don’t take a baseball and bat. Similarly, if you are selling certain products in Europe, forget about your Underwriters Laboratory certification.

To export to the 27 member states of the European Union, what’s required is CE certification – Conformité Européenne, French for European conformity, documentation that a product has met essential health and safety requirements set by the EU.

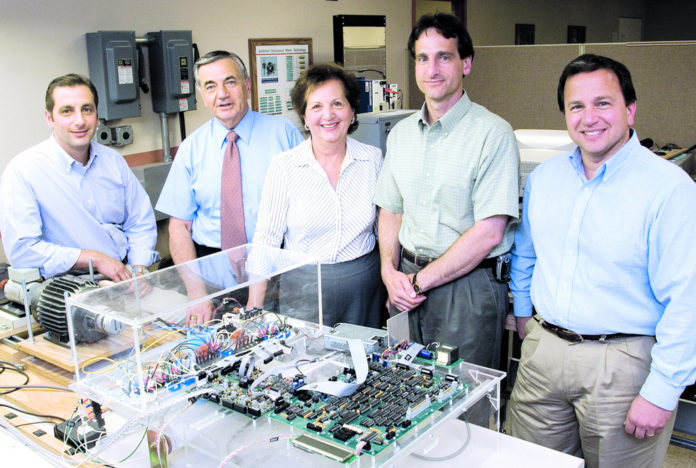

Electro Standards Laboratories, a 30-year-old Cranston manufacturer of hardware for telecommunications networks, went through a process about three years ago to acquire CE certification for a precision measuring instrument in its stable of products.

The instrument can be used with sensors measuring stresses on an airplane wing during manufacture and testing, among other applications, said company President Raymond Sepe.

Getting CE certification was worthwhile, Sepe said, because it led to sales of the instrument directly to European companies and, equally important, to American-based companies using that instrument in Europe.

“It would stunt U.S. sales if U.S. manufacturers could not use [the instrument] in Europe,” Sepe noted.

The company found a testing lab in Massachusetts that does CE certification and training, and it not only had the specific instrument certified, but also got qualified to self-certify products it might create in the future, provided that CE standards are followed.

The payoff has been substantial: A 10- to 11-fold increase in overall sales from 2005 to 2006, Sepe said – partly, but not entirely, due to the CE approval – and in the first two months of 2007, sales are 78 percent higher than in 2006.

“As we put more products into the international market, we are closer to becoming a household name,” Sepe said.

The cost of the training was covered in part by a grant from the R.I. Economic Development Corporation, which provides export management training grants of up to $5,000 to Rhode Island companies.

Kathy Tufts, associate international trade director for the EDC, said the grants were initiated in 1997, and several companies have used them to pay for CE certification training, including Heartlab in Westerly, which qualified to sell a cardiac imaging product in Europe; and Yushin America Inc. in Cranston, which makes robots for the injection-molded plastics industry.

Training and compliance for CE certification is a very complicated process, Tufts said, and companies usually need to hire specialists – such as testing and certification services or engineering consulting groups – to help them decipher the CE directives.

The EDC tracks the progress of companies after they have used an export management training grant, and in responses a year after certification, companies report a “phenomenal” increase in business to Europe, Tufts said. (Often, companies are seeking certification because they already have potential sales leads from European companies.)

Tufts could not provide statewide figures for increases in European sales as a result of new CE certifications. But exports from Rhode Island to Europe (including Turkey, not an EU member), rose from $344 million in 1997 to $447 million in 2006, a 30-percent increase, according to figures from the U.S. Census Bureau’s Foreign Trade Division. (For comparison, total exports from Rhode Island rose 50 percent during that period.)

For Electro Standards, CE certification was only the first step in an ongoing process of restructuring. By using its knowledge in communications, data acquisition and fiber optics, combined with recent marketing through the Internet, Electro Standards is re-forming itself as a quick-response company that can make customized products, outsource subassembly overseas, finish the assembly in the U.S., and push the product into the supply chain.

CE certification and access to the European market “opened the door” to helping Electro Standards become more well-known, versatile, and flexible, Sepe said.

“It was the first domino,” he said, “and we are about 12 dominoes in now.”