Nye Lubricants inc.

Overall Excellence, 150-499 employees | 2019 PBN Manufacturing Awards

Any company that has a founder related to TV star, inventor and best-selling author Bill Nye “The Science Guy” is already interesting.

But add the fact that Nye Lubricants Inc. has been around since the 1800s – it first produced watch oil made from the jaws of porpoises – and now makes lubricants for uses such as the Mars Curiosity rover, and it’s an even better story.

From oceans to outer space, Fairhaven-based, 180-employee Nye Lubricants has a long legacy of innovation – improvements it continues to strive for in developing specialty greases and oils.

“We have always been linked to innovation,” said company President and CEO George Mock. “Vacuum equipment … the aerospace market; new, electric and hybrid automobiles. Our products are technologies that help make [customers’] products work better.”

Nye Lubricants was founded in Fairhaven by William Foster Nye in 1844. Bill Nye is a direct descendant of the founder’s brother.

With more than $50 million in sales, the company has 28 channel partners that produce 50 percent of its demand outside of the United States. Nye’s customers include manufacturers of clean-room equipment, appliance and power tools, medical devices and renewable-energy equipment.

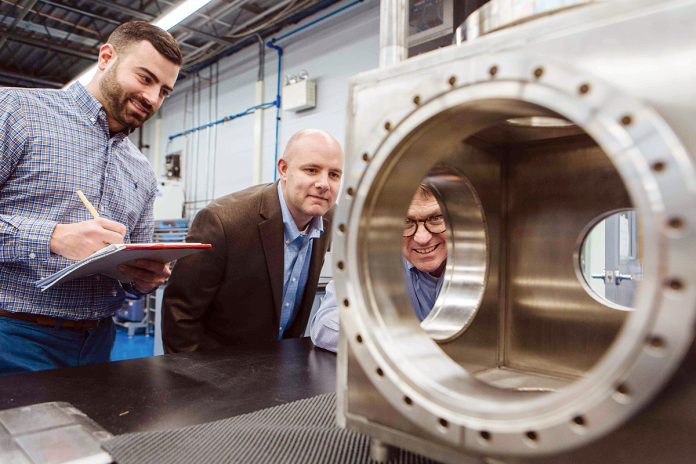

Its complex in Fairhaven is 83,000 square feet, with administrative offices, research-and-development labs, clean-room operations and production lines. And the labs are especially important, Jason Galary, director of research and development, said in a company video. That’s where unique synergy happens between Nye engineers and the clients’ engineers.

“What differentiates us is … our approach to working directly with our customers to simulate their applications … and to be there during the whole design process to help them solve their problems,” he said.

The company works alongside its clients, but it also looks ahead.

Nye is a leader in emerging technologies, said Torsten Brieger, strategic marketing manager, calling its integration of industrial internet of things a perfect example. IIOT collects data in manufacturing equipment that can be used to make improvements.

“It sees the data on the manufacturing processes and involves machine learning,” Brieger said. “We can be getting updates to our phones on processes, mix times, cool times. Basically, right after something happens, there is an instant notification for that kettle” and its status, he said.

‘Our products are technologies that help make [customers’] products work better.’

GEORGE MOCK, Nye Lubricants president and CEO

Optimization is the goal, according to Kathleen Landers, marketing supervisor.

“We are trying to continually improve and practice lean processes,” including waste reduction and time efficiencies, with IIOT allowing new insight and consistent outcomes, she said.

New insight is a base for the innovation for which Nye is known.

The company owns one of only five Spiral Orbit Tribometer testers in the world; the others are owned by NASA. The tribometer allows the company to simulate high-vacuum conditions such as those present in space to best examine how its products would perform in that environment.

In addition to partnerships with NASA, Nye has worked with major aerospace companies such as Northrop Grumman and Lockheed Martin, as well as the intergovernmental European Space Agency.

Nye has ISO certifications for the aerospace, automotive and medical industries. It is on the Department of Defense’s Qualified Provider List for its specialty grease used to maintain U.S. Navy jets. At the same time, its lubrication products are in commonplace items: power drills, washing machines and cellphones, for example.

Along with many of its customers, Nye has cut its overall environmental impact, especially over the past decade.

Volatile organic compound levels have been reduced, according to Nye. One of the ways it works to reduce its carbon footprint is by recycling lubrications that don’t meet specifications – selling it to manufacturers of general-purpose grease, for example – and using as few hazardous materials as possible.

Environmental stewardship, and close customer collaboration breed success for Nye.

“The entire thing is a partnership,” Landers said. “We speak their language.”